Project Spotlight: AFRL Mechanical Ventilation Simulation

About AFRL and the Human Effectiveness Directorate

The Air Force Research Laboratory (AFRL) is dedicated to leading the discovery, development, and integration of innovative technologies for the U.S. Air Force. The Human Effectiveness Directorate focuses on optimizing human performance and ensuring the health and safety of Air Force personnel.

AFRL identified the need to improve training for clinicians who provide mechanical ventilation (MV) to patients, especially in military settings. MV is crucial for combat casualties and patients with conditions like ARDS, chronic lung diseases, acute lung injuries, and trauma. The need for prolonged care, complex environments, and transport scenarios adds to the challenge. Skill decay due to limited exposure to high-acuity patients also exacerbates the problem.

Inadequate training and skill decay can lead to suboptimal patient outcomes and increased complications during MV. This affects both public and military healthcare providers, with significant implications during pandemics or mass casualty events. Effective training solutions are critical to ensuring that clinicians can provide high-quality care in all settings.

Advancing Mechanical Ventilation Training through Simulation

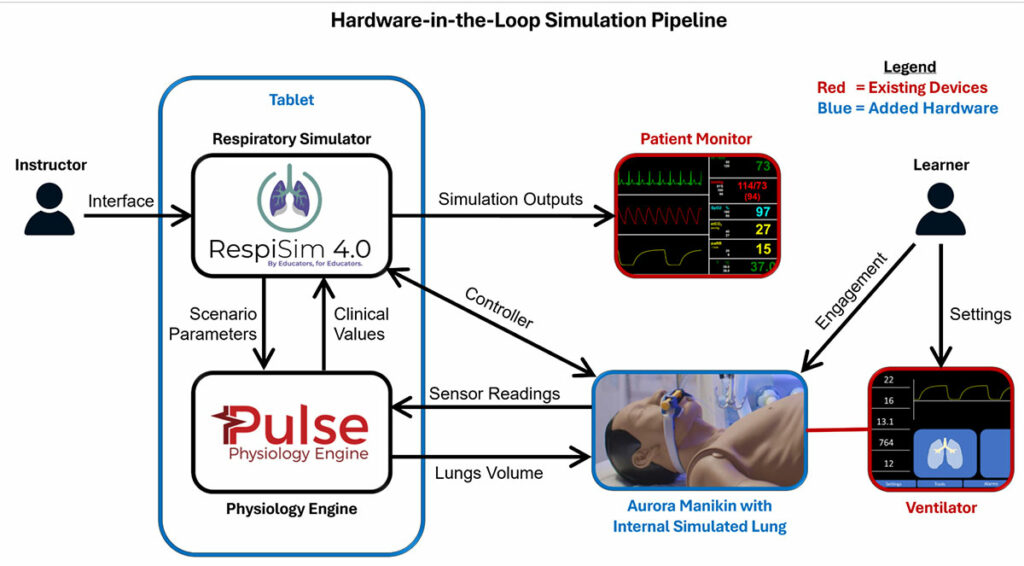

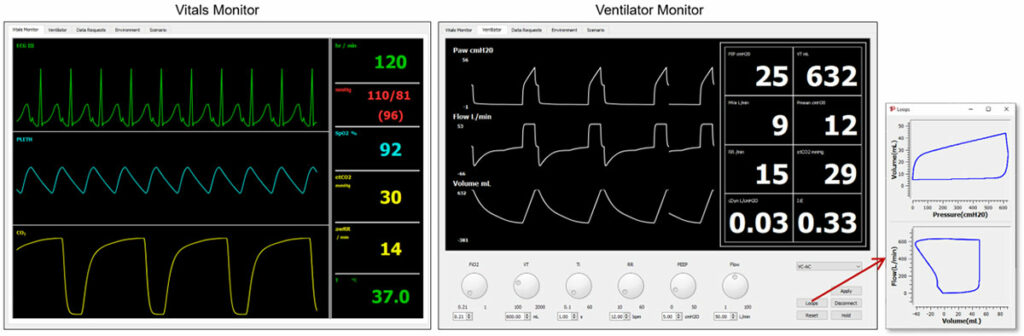

AFRL’s Air and Space Biosciences Division Product Development Branch En Route Care Section is collaborating with the University of Cincinnati, IngMar Medical, and Kitware to develop a prototype for an all-in-one advanced ventilator simulator (AVS) for training in mechanical ventilation. This simulator uses validated scenarios based on ARDS Network (ARDSnet) and Joint Trauma Clinical Practice Guidelines, allowing clinicians to practice and improve their skills in providing mechanical ventilation without a human trainer. The technology provides real-time feedback and debriefs after each scenario, enhancing the training experience.

Kitware is combining our expertise in computational physiology and simulation to help create the AVS. We are integrating the Pulse Physiology Engine to create realistic training environments and provide actionable feedback to users. Unlike instructor-driven or state-based approaches, Pulse uses physics-based, mechanistic models to dynamically simulate whole-body physiology in real time for unparalleled realism.

The AVS incorporates physiological modeling to provide realistic patient responses, validated scenarios to ensure clinical relevance, and automated feedback mechanisms to enhance learning. These innovative approaches ensure that clinicians can practice MV management in a controlled, yet highly realistic environment.

As part of this effort, we are interfacing with Prof. Robert L. Chatburn, MHHS, RRT-NPS, FAARC to validate that Pulse is appropriately and credibly simulating ventilated patients with ARDS and COPD. The primary objective is to ensure consistency with current/emerging best practices and guidelines. The mechanical ventilator equipment model is used as a synthetic surrogate to physical hardware to aid efficient development as well as model verification and validation. Our comprehensive analysis has shown good outcome alignment with empirical data.

Results and Impact

The AVS provides realistic and advanced training scenarios for clinicians. It addresses the training gap identified by AFRL and has shown potential for widespread use in both military and civilian healthcare settings. By providing realistic scenarios and immediate feedback, the solution enhances clinicians’ skills and confidence in using MV. Initial results are presented in the Phase I report.

The simulator leads to improved competency scores in training evaluations, reduced skill decay, and enhanced readiness for real-world scenarios. We have received positive feedback from stakeholders on the realism and effectiveness of the training scenarios, increased confidence in managing MV, and better preparedness for emergencies.

The AVS will continue to evolve with additional scenarios and improved features. It aims to become a standard training tool for both military and civilian clinicians, ensuring high-quality care for patients requiring mechanical ventilation.

For more information about the Pulse Physiology Engine and how it can be integrated with your medical device or software, send us a message.

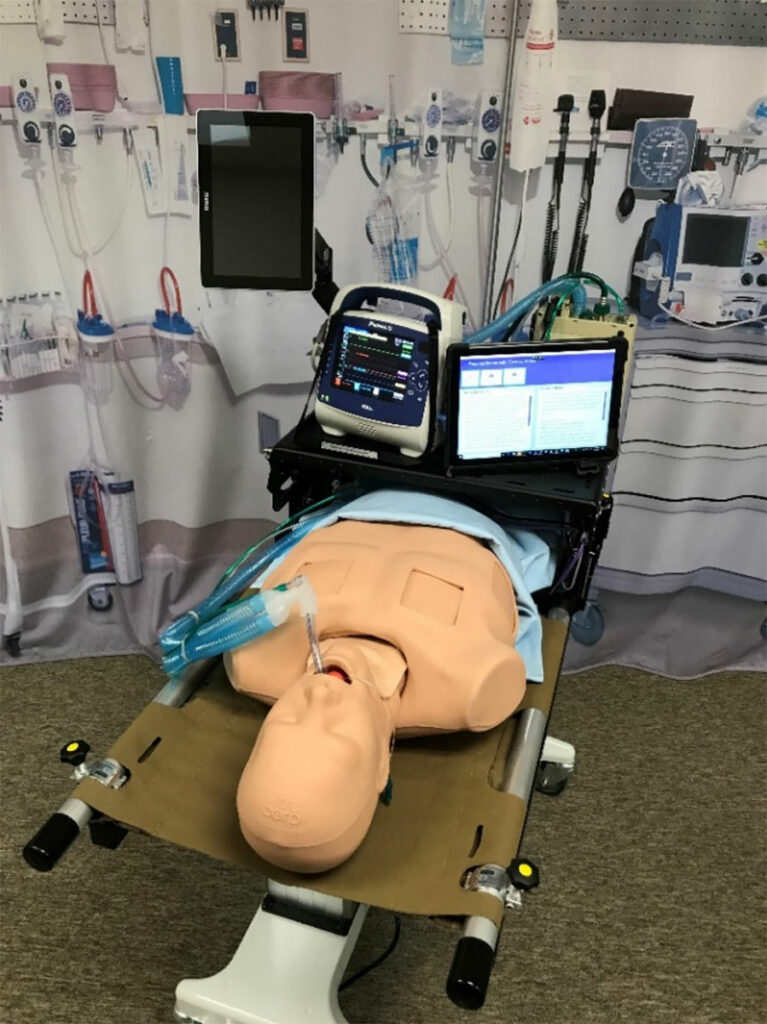

Caption for Featured Image: Prof. Richard Branson, MSc, RRT, FAARC, FCC, showcases the advanced mechanical ventilator simulator prototype to stakeholders at Wright-Patterson Air Force Base.