Make Your Automotive Simulation Tools Available on the Web

We use websites to do everything, from communicating with friends and family and paying bills, to shopping for cars, and visiting the doctor. Even at work we rely heavily on the web because it provides a platform for wide-spread and easy access to applications. Web browsers are highly effective at delivering applications with excellent user experiences.

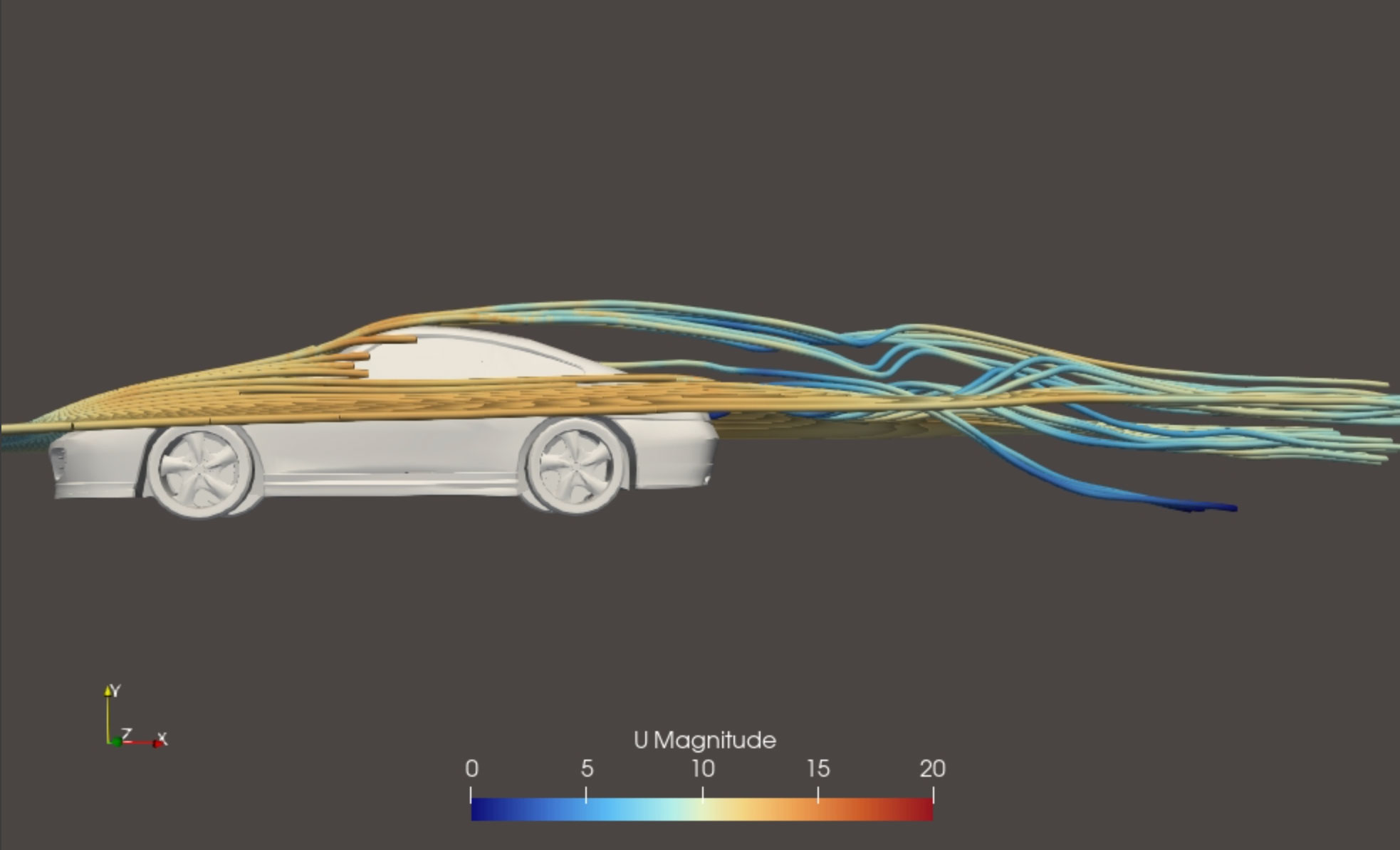

It’s only natural, then, for engineers to also want easy access to web solutions for their design and simulation modeling. For automotive engineers in particular, having easy and shared access is critical since the overall process involves large teams of engineers and designers working on different parts of the automotive design problems. While tasks such as setting up, running, and analyzing simulations of automobile parts and components have historically been done with desktop software on high-end workstations or on high-performance computers involving proprietary product management systems, these can now all be handled on the web.

Simplifying workflows

Depending on the simulation technology, developing each product or component simulated typically involves the following workflow::

- Model creation using CAD or another modeling technique

- Mesh creation

- Preprocessing to define material properties, boundary conditions, and other initial conditions

- Running the simulation itself

- Post-processing and analysis to determine results

Simulation workflows have been around for decades, but executing them is not always as easy as it could be. Each step in a workflow may require using disparate, specialized tools, each with its own quirks and limitations. In addition, many automotive workflows require physics to be modeled requiring multiple sub-workflows with different geometry, meshes, simulation information, and solvers. The use of all these tools to set up simulations can be difficult – making it easier would help automotive design engineers. This is supported by 2023 survey of computational fluid dynamics (CFD) software trends by Engys where 47% of respondents agreed that easier model preparation for simulation would significantly help them in their CFD projects.

Simulation software companies are seeing a demand for integrated and easier to use software packages, and are responding in their latest software releases. Recently, popular simulation software packages such as Fluent from Ansys, HyperWorks from Altair, and Fidelity from Cadence have focused on integrating their simulation tools under more intuitive user interfaces. The end goal is to provide a unified interface to the entire workflow to improve efficiency and reduce the costs associated with simulation.

In addition to providing unified interfaces to different parts of the workflow, modern simulation software is also providing more simplified workflows. These workflows expose only key parameters of a simulation scenario and hide away the full complexity of the simulation tools available. Simplifiying workflows increase the number of engineers who can access simulation tools in a way that is meaningful to their expertise, without requiring them to be experts in the full details of the simulation software.

The web advantage

The broad accessibility of web applications means that people can more easily access their work and share information with colleagues and customers. If a unified interface to simulation software is made available through the web, then everyone with an internet connection and web browser can readily create and access simulation results. The ubiquity of web browsers on devices means people can access web applications from their laptops, workstations – even their smartphones. Contrast this to the long-time status quo where running simulations was limited to workstations or high-performance computer systems where data must be processed and reports generated before distribution of results is possible.

Web applications also remove the burdens inherent in installing and keeping software up to date on desktop or laptop systems. Software upgrades and enhancements happen behind the scenes, letting web users focus on the task at hand rather than wrangling software. Centralized installation reduces the system administration required to provide simulation and modeling tools.

Stepping into the future

The trend towards simplified workflows in simulation software is encouraging and something we will see much more of in coming years. Engineers would rather focus on the engineering problem they are trying to solve rather than problems with their simulation workflow and software tooling. By packaging workflows nicely and making them accessible on the web, simulation solution providers will provide great cost savings to their customers as time-to-solution is reduced and increase demand for their software as access to it is broadened across the enterprise.

Automotive manufacturers can see additional benefits by expanding the use of simulation by people who are not computational scientists but need the results of simulations to make engineering or process decisions. One way to do this is for a simulation expert to provide curated simulations they can run and analyze themselves, eliminating expensive bottlenecks that can happen when only expert computational scientists can run needed simulations. With the rise of digital twins that inform real-world system operations based on simulation scenarios, this broader access will be essential in maximizing the value they bring to manufacturing and logistics.

Kitware has extensive experience in providing accessible simulation workflows on the web. By using a framework like trame, we can dynamically generate user interfaces for input parameters to set up a simulation and integrate state-of-the-art web-ready rendering solutions like VTK and ParaView for post-processing when the simulation is running or finished. We can help or build it all for you and help with your web strategy to simplify your customer’s lives. If you want to learn more on how Kitware can help you, please contact us.

You can learn more about Kitware’s efficient simulation workflow solutions for automotive manufacturers by visiting our Automotive Solutions page.